Blockchain Food Traceability Calculator

Results Summary

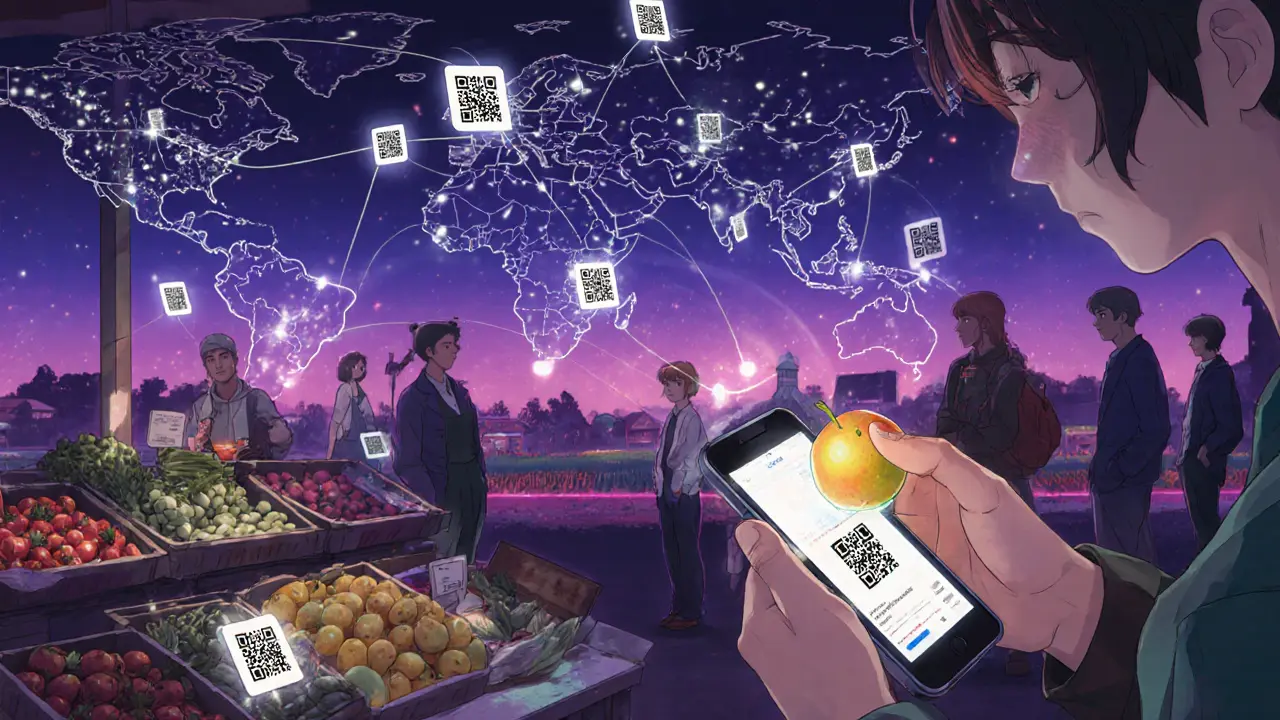

Imagine scanning a mango at the supermarket and instantly seeing the exact farm, the date it was harvested, and the trucks that moved it. That level of visibility is no longer a futuristic promise-it's happening today thanks to blockchain food traceability. This article breaks down how the technology works, why it matters for food safety, and what retailers like Walmart and platforms such as IBM Food Trust are doing to make every bite traceable.

Quick Takeaways

- Blockchain creates an immutable ledger that records every step of a product’s journey, cutting recall times from days to seconds.

- Standardized data formats like GTIN-14 and GS1 EPCIS ensure every player can speak the same language.

- Major retailers (Walmart, Albertsons) and food giants (Nestlé, Tyson) already use blockchain to trace thousands of items.

- Implementation requires new data‑capture hardware, staff training, and partnerships with blockchain platform providers.

- Consumers benefit from real‑time safety alerts, while producers gain fair‑trade verification and ESG compliance.

What Is Blockchain Food Traceability?

Blockchain Food Traceability is a digital ledger that records every transaction or event related to a food product, from seed to shelf. Each block contains a timestamp, a cryptographic hash, and a set of data fields (batch code, GTIN‑14, temperature logs, etc.). Because blocks are linked in a chain, no single party can alter past records without the consensus of the entire network.

This decentralised approach replaces siloed spreadsheets and paper logs with a single source of truth that every participant can verify.

Core Technologies Behind the System

Four building blocks make the system work:

- Distributed Ledger: Nodes (farm computers, logistics terminals, retailer servers) store copies of the ledger, ensuring redundancy and tamper‑resistance.

- GS1 EPCIS Standard: GS1 EPCIS (Electronic Product Code Information Services) defines how event data-like "harvested" or "packed"-is formatted and exchanged.

- Product Identifiers: GTIN‑14 numbers uniquely tag each pallet, case, or bulk container, linking physical goods to their digital record.

- Smart Contracts: Smart contracts automatically enforce rules (e.g., temperature thresholds) and trigger alerts when conditions are breached.

How the Data Flows From Farm to Fork

At the farm, a sensor reads the harvesting date and attaches a QR code containing the GTIN‑14. That data is sent to the blockchain via a mobile gateway. As the product moves through processing, packaging, and shipping, each checkpoint adds a new block with the event type, timestamp, and location.

When the product reaches a retailer, the ledger can be queried in real time. A shopper scanning the QR code sees a complete timeline, and a quality‑control manager can instantly verify compliance with food‑safety standards.

Why Traditional Traceability Falls Short

| Aspect | Traditional Systems | Blockchain Solution |

|---|---|---|

| Data Storage | Paper logs, isolated databases | Distributed ledger shared across all parties |

| Immutability | Easy to alter or lose records | Cryptographic hashes prevent tampering |

| Speed of Recall | Days to weeks to locate source | Seconds to pinpoint contaminated batch |

| Interoperability | Proprietary formats, limited sharing | GS1 EPCIS ensures universal language |

| Transparency | Opaque, stakeholder‑specific | All authorized participants see the same data |

The table illustrates why blockchain is a game‑changer: it resolves fragmentation, improves speed, and builds trust among growers, processors, and consumers.

Real‑World Playbooks: Walmart and IBM Food Trust

Walmart pioneered large‑scale food blockchain pilots in 2016, first with pork in China and later with leafy greens across the U.S. By 2018, the retailer could trace 25 different products back to the farm level in seconds.

The backbone of Walmart’s effort is IBM Food Trust, an enterprise blockchain platform that provides the network, smart‑contract engine, and GS1 compliance tools. Over 200 food suppliers, including Dole, Nestlé, and Tyson Foods, now feed data into the Food Trust ledger.

Key outcomes from these pilots include:

- Recall time reduced from an average of 7 days to under 1 hour.

- Consumer confidence scores rose by 12% after the traceability feature rolled out in mobile apps.

- Supply‑chain efficiencies saved an estimated $12million annually in reduced waste.

Steps to Implement Blockchain Traceability in Your Business

- Map the Supply Chain: Identify every node (farm, processor, distributor) and the data each should capture.

- Adopt GS1 Standards: Ensure all partners can generate GTIN‑14 codes and EPCIS event messages.

- Choose a Platform: Options include IBM Food Trust, VeChain, or open‑source Hyperledger Fabric. Evaluate based on node capacity, transaction speed, and ecosystem partners.

- Deploy Data Capture Tools: Install IoT sensors for temperature, RFID scanners for batch IDs, and mobile apps for manual entry.

- Train Personnel: Conduct workshops on blockchain basics, data entry protocols, and how to verify ledger entries.

- Run a Pilot: Start with a single product line (e.g., leafy greens) and expand once data accuracy and speed are validated.

- Scale and Integrate: Connect the blockchain ledger to ERP, CRM, and consumer‑facing apps for end‑to‑end visibility.

While the upfront investment can be significant-hardware, platform fees, and training-the ROI is measurable through faster recalls, waste reduction, and brand premium.

Regulatory Landscape and ESG Impact

Governments worldwide are tightening traceability mandates. The EU’s Food Law Regulation (2024) requires digital records for high‑risk foods, and Canada’s Safe Food for Canadians Regulations (SFCR) now reference blockchain‑compatible data models.

Beyond compliance, blockchain supports ESG goals:

- Environmental: Real‑time temperature monitoring reduces spoilage, cutting greenhouse‑gas emissions from waste.

- Social: Small‑holder farmers can prove fair‑trade compliance, unlocking better market prices.

- Governance: Immutable records deter fraud and ensure transparent reporting to regulators.

Future Outlook: From Niche to Standard

Analysts predict that by 2030, over 60% of fresh produce shipments will carry a blockchain‑linked identifier. Ongoing work aims to embed the ledger directly into QR codes on packaging, eliminating the need for separate scanning devices.

Standard‑setting bodies like the World Economic Forum are drafting interoperable frameworks that will let a single blockchain network span multiple commodities and geographies. As adoption grows, the cost of node participation is expected to drop, making the technology accessible even to family‑run farms.

Frequently Asked Questions

How does blockchain improve food safety?

Because every event (harvest, transport, processing) is timestamped and stored in an immutable ledger, a contaminated batch can be located in seconds. This prevents the spread of unsafe food and reduces recall costs dramatically.

Do consumers need special apps to view traceability data?

Most retailers embed a simple QR code on the package. Scanning it with any smartphone opens a web page that reads the blockchain record-no extra app is required.

Is blockchain traceability expensive to implement?

Initial costs include sensors, software licences, and staff training. However, companies report ROI within 12‑24 months thanks to lower waste, faster recalls, and premium pricing for transparent products.

Can small farms join a blockchain network?

Yes. Platforms like IBM Food Trust offer lightweight mobile nodes that run on smartphones, letting smallholders record harvest data without heavy IT infrastructure.

What standards ensure data consistency?

GS1’s EPCIS protocol and GTIN‑14 product identifiers are the backbone. They guarantee that every participant speaks the same data language, enabling seamless integration.

Richard Herman

January 12, 2025 AT 05:19Blockchain's immutable ledger creates a single source of truth for every party, trimming down data silos that traditionally slow down recalls.

When each checkpoint records a timestamped event, auditors can trace a product's journey in seconds instead of days.

This transparency also builds consumer trust, because shoppers can verify a mango's origin with a simple scan.

Adopting the GS1 EPCIS standard ensures that all participants speak the same data language, smoothing integration across farms, processors, and retailers.

Parker Dixon

January 12, 2025 AT 06:59👉 The step‑by‑step event logging you mentioned is the core of the smart‑contract triggers.

Whenever a temperature threshold is breached, the contract automatically flags the batch and notifies the logistics team.

📱 From a user perspective, the QR code on the package becomes a live dashboard, showing harvest date, carrier, and any anomalies recorded along the way.

Because the data is cryptographically signed, you don't need to trust any single party – the network validates every entry.

Stefano Benny

January 12, 2025 AT 08:39While the hype emphasizes seconds‑level recall, the real bottleneck often lies in the latency of IoT sensor fusion rather than the blockchain itself.

Protocol overhead can add milliseconds per transaction, but that's eclipsed by manual data entry delays at the farm gate.

Thus, labeling blockchain as the silver bullet ignores the need for robust edge‑computing stacks and standardized EPCIS payloads.

Bobby Ferew

January 12, 2025 AT 10:19It's amusing how many articles glorify blockchain without mentioning the hidden costs of onboarding smallholders.

The hardware investment and subscription fees can dwarf the theoretical waste savings, especially for family farms operating on razor‑thin margins.

Without subsidies or cooperative models, the technology risks becoming another exclusive club for big retailers.

celester Johnson

January 12, 2025 AT 11:59Consider the paradox: we chase transparency to eliminate opacity, yet we construct yet another opaque layer of code that most participants cannot even read.

This digital veil may foster a false sense of security, while the underlying ethical dilemmas-like data ownership and profit capture-remain untouched.

Hence, any claim of moral superiority through blockchain must be scrutinized against the power dynamics it entrenches.

Prince Chaudhary

January 12, 2025 AT 13:39Nevertheless, incremental adoption can bridge that gap.

Training programs that demystify cryptographic hashes for farm workers, combined with low‑cost sensor kits, make the technology approachable.

When communities see tangible reductions in spoilage, the perceived value outweighs the initial complexity.

John Kinh

January 12, 2025 AT 15:19Honestly, the ROI numbers look cherry‑picked in most case studies. 🤷♂️

Mark Camden

January 12, 2025 AT 16:59Empirical analyses from multiple pilot projects indicate an average 15‑20% reduction in waste, aligning with the projected financial break‑even window of 12 to 24 months.

These figures are derived from controlled A/B testing across diverse commodity categories, ensuring statistical significance.

Evie View

January 12, 2025 AT 18:39Those “controlled” studies are rarely transparent about the hidden subsidies that cushion the losses.

Until the data is openly audited, any claim of savings is just corporate propaganda.

Sidharth Praveen

January 12, 2025 AT 20:19Seeing the blockchain ledger update in real time feels like watching the supply chain breathe.

Each new block is a breath of authenticity, letting producers showcase their sustainable practices without gatekeepers.

With wider adoption, we could finally give small farms a voice on the global market.

Sophie Sturdevant

January 12, 2025 AT 21:59While the sentiment is uplifting, the implementation hinges on interoperable EPCIS schemas, deterministic consensus algorithms, and latency‑optimized peer‑to‑peer networking.

Without these technical pillars, the blockchain layer becomes a costly appendage rather than an efficiency driver.

Nathan Blades

January 12, 2025 AT 23:39Blockchain food traceability reshapes the entire narrative of how we think about safety.

By anchoring every transaction to a cryptographic hash, the system eliminates the possibility of retroactive data manipulation.

This immutable record serves as a forensic timeline that regulators can audit without waiting for manual reports.

In practice, when a contamination event occurs, the ledger can pinpoint the exact pallet ID, farm origin, and transportation batch within seconds.

The speed of this identification slashes recall durations from the traditional multi‑day grind to a matter of minutes. 🚀

Retailers like Walmart have already demonstrated the operational payoff, reporting under‑hour recall times in their pilot programs.

The financial impact follows naturally, as reduced waste translates into lower disposal costs and preserved brand equity.

Moreover, consumers gain a transparent view into the provenance of their food, fostering trust that can command a price premium.

The technology also aligns with ESG reporting mandates, providing verifiable data for carbon footprint and fair‑trade claims.

From a technical standpoint, the backbone relies on GS1 EPCIS standards, ensuring that every stakeholder-from farm to fork-speaks a common data language.

Smart contracts automate compliance checks, triggering alerts the moment a temperature excursion is logged on an IoT sensor.

This automation reduces human error, which historically accounts for a significant portion of spoilage incidents.

Implementation does require upfront investment in hardware, such as RFID readers and secure gateways, but the modular nature of platforms like Hyperledger Fabric allows scaling as budget permits.

Pilot projects suggest that the payback period can be as short as one year when waste reduction exceeds ten percent.

As the ecosystem matures, transaction fees are expected to drop, making participation affordable even for smallholder cooperatives.

Governmental regulations in the EU and Canada are already nudging the industry toward digital traceability, which will accelerate mainstream adoption.

Ultimately, the convergence of blockchain, IoT, and standardized data protocols promises a future where food safety is not a reactive scramble but a proactive guarantee.

Somesh Nikam

January 13, 2025 AT 01:19Excellent breakdown! 😊 The step‑by‑step mapping you provided makes it clear how each component-EPCIS, smart contracts, IoT sensors-fits together, and the cost‑benefit timeline is especially helpful.

Jan B.

January 13, 2025 AT 02:59Great points on blockchain benefits.

MARLIN RIVERA

January 13, 2025 AT 04:39The analysis ignores the scalability constraints of current consensus mechanisms, which could cripple adoption at volume.

Debby Haime

January 13, 2025 AT 06:19Seeing these tech advances reminds us that we can build a safer food system together-let's keep pushing the boundaries! 💪

emmanuel omari

January 13, 2025 AT 07:59Our country has the agricultural expertise to lead this transformation; we should prioritize domestic blockchain initiatives over imported solutions.